Engine Partners With US Sydney For SBS Immigration Nation

According to Engine EP Adam Wells the promos they recently created for SBS’ new documentary series Immigration Nation: The Secret History of Us have raised more than a few eyebrows.

Wells explained, “The project came about after our CD Simon Robson (Knife Party) and I met with the team at Us Sydney. They presented four scripts for promos about a 3-part documentary series tracing Australia’s chequered immigration policy from the 1900s to the present day. With that kind of subject matter it was clear controversy wasn’t going to be far away.”

Robson took away the four scripts, one for a ‘coming soon’ promo and the others all based around specific time periods from the White Australia policy to multiculturalism and began work on developing the concepts. Engine’s Producer on the Immigration Nation promos Amelia Peacocke said, “Immigration Nation was a thoroughly inspiring project to work on with the agency and Engine teams developing a very creative and trusting relationship on the production. One of the challenges we came across was how best to showcase the idea that the talent in each of the three episodes was holding a dark secret buried beneath their positive message about Australia's immigration policy. The agency came to Engine with the challenge of making the characters spin around and develop an execution that saw the talent being shot and composited so that they appeared to be the same person back to back. The execution of this idea really helped to really drive home the message.”

The Engine team had three set time periods to work with, the 1900s, 1950s and the present day – one for each episode of the series. Robson added, “A point to note here is that the ‘back to back’ post production effect in each promo where, when the character finishes their piece, they spin 180 degrees on a turntable to highlight the two-faced and double-sided slant to some of Australia’s immigration policies also represents Australia’s alter-ego - the small print or terms and conditions that went hand in hand with the practical come one, come all message.”

For the 1900’s promo Robson and his team cast and selected talent for a dark silent film. In the 1950’s promo Robson used the same format but this time casting a post war UK cinema style ‘Walter Kronkite’ figure with a visual projected behind him ‘Hitchcock-style’, selling Australia as the land of fertility where everyone could come and build a great future. When the character flips to his alter ego the background visual burns out leaving only the brutal reality of the real terms and conditions for entry.

Robson added, “Both spots from the past were meant to cause a reaction and raise eyebrows. The modern day promo takes it one step further with a female current affairs pundit selling today’s benefits of Australia’s great multi-cultural approach only to flip as the studio environment darkens to reveal the true terms and conditions over the course of history.”

Perhaps the most impactful of the four promos was the ‘coming soon’ spot which also proved creatively challenging as it needed to deliver a very complex message.

Robson explained, “The client and agency had seen some of my past work including Taking Liberties and What Barry Says which involve interesting animation and typographical effects and wanted these looks for the ‘coming soon’ promo. This gave us great scope to create something unusual for Australian television.”

Robson creatively directed the services of top illustrator Pete McDonald and worked with the typography skills of Luca Ionescu of Like Minded Studios, brought on board by US Sydney to work on the project, to bring together a series of unique elements for the spot.

Robson continued, “This is very much the model and approach used by large international agencies – bring in the best talent for each job and work with them in-house. It worked really well with Pete and Luca’s clever images and typography helping to create a ‘moving stream of consciousness’ where Utopian messages revealed themselves in the landscape, before coming abruptly to a halt to deliver the sobering truth. As a result the ‘coming soon’ promo communicates a real Australian narrative that depicts our natural resources of wheat, meat and timber and cleverly integrates them with the mixed messages around immigration.”

Engine’s Senior Flame Artist Lee Sandiford was then tasked with doing an authentic grade for each era. As Sandiford explained, there were some particular creative challenges that needed to be overcome. He said, “We did an initial test on a basic version of the concept, showed it to the client and they loved it. Each era had a different look, feel, grade and colour. The blacks and whites were different and we had to degrade the images and footage to make them look like an old film reel that was suffering with too much light from a non-existent projector. The 180-degree turnaround effect had to be fast enough to be snappy but slow enough that the viewer can see it’s two sides of the same person.”

According to Adam Wells the SBS Immigration Nation promos are very much the shape of things to come for the company. He concluded, “This is a very good example of a complete top to tail campaign done completely at Engine. From casting, wardrobe, shooting footage and creating characters through 2D, 3D and post it was all taken care of by our in-house team. This is something that we are being asked to do more and more of and we see very much as the future of our industry.”

Immigration Nation aired at 8.30pm on Sundays on SBS One. To view the promos and for more information on Immigration Nation go to: http://www.behance.net/gallery/IMMIGRATION-NATION/893164

And http://www.sbs.com.au/immigrationnation

Credits:

Client: SBS

Agency: US Sydney

Production Company: Engine

Director: Simon Robson

US Sydney / Creatives:

Alex Tracy (Account Director)

Josh Moore (Executive Creative Director)

Nigel Clark (Copywriter)

Tim Chenery (Art Director)

Amelia Peacocke (Producer)

Sacha Moore (Agency Producer)

Tim Stuart (Account manager)

Animation Credits:

Executive Producer: Adam Wells

Typography: Luca @ Like Minded

Illustration: Pete J McDonald

Lead 2D animation: Robert Grieves

Animation: Marko Pfann

3D: Shaun Schellings & Dam

digunakan untuk kecepatan tinggi dan penggerak generator elektrik pada abad 19.

digunakan untuk kecepatan tinggi dan penggerak generator elektrik pada abad 19.

dikembangkan tahun 1816 untuk menyaingi steam engine. kelebihan: efisiensi tinggi, tidak bising, dapat menggunakan sumber tenaga panas dari apa saja.

dikembangkan tahun 1816 untuk menyaingi steam engine. kelebihan: efisiensi tinggi, tidak bising, dapat menggunakan sumber tenaga panas dari apa saja.

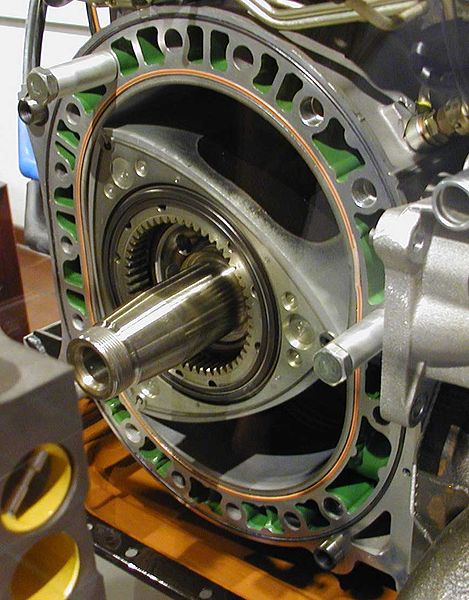

dikenal dengan mesin yang irit, efisiensi tinggi, dan ramah lingkungan. digunakan pertama kali oleh citroen M35, lalu digunakan mazda Eunos Cosmo, RX7, dan RX8.

dikenal dengan mesin yang irit, efisiensi tinggi, dan ramah lingkungan. digunakan pertama kali oleh citroen M35, lalu digunakan mazda Eunos Cosmo, RX7, dan RX8.

We all have our favorite radio stations that we preset into our car radios, flipping between them as we drive to and from work, on errands and around town. But when you travel too far away from the station, the signal breaks up and fades into static. Most radio signals can only travel about 30 or 40 miles (48 to 64 kilometers) from their source. On long trips, you might have to change radio stations every hour or so as the signals fade in and out. And it's not much fun scanning through static trying to find something -- anything -- to listen to.

We all have our favorite radio stations that we preset into our car radios, flipping between them as we drive to and from work, on errands and around town. But when you travel too far away from the station, the signal breaks up and fades into static. Most radio signals can only travel about 30 or 40 miles (48 to 64 kilometers) from their source. On long trips, you might have to change radio stations every hour or so as the signals fade in and out. And it's not much fun scanning through static trying to find something -- anything -- to listen to.

There are several engine types which are identified by the number of cylinders and the way the cylinders are laid out. Motor vehicles will have from 3 to 12 cylinders which are arranged in the engine block in several configurations. The most popular of them are shown on the left. In-line engines have their cylinders arranged in a row. 3, 4, 5 and 6 cylinder engines commonly use this arrangement. The "V" arrangement uses two banks of cylinders side-by-side and is commonly used in V-6, V-8, V-10 and V-12 configurations. Flat engines use two opposing banks of cylinders and are less common than the other two designs. They are used in engines from Subaru and Porsche in 4 and 6 cylinder arrangements as well as in the old VW beetles with 4 cylinders. Flat engines are also used in some Ferraris with 12 cylinders

There are several engine types which are identified by the number of cylinders and the way the cylinders are laid out. Motor vehicles will have from 3 to 12 cylinders which are arranged in the engine block in several configurations. The most popular of them are shown on the left. In-line engines have their cylinders arranged in a row. 3, 4, 5 and 6 cylinder engines commonly use this arrangement. The "V" arrangement uses two banks of cylinders side-by-side and is commonly used in V-6, V-8, V-10 and V-12 configurations. Flat engines use two opposing banks of cylinders and are less common than the other two designs. They are used in engines from Subaru and Porsche in 4 and 6 cylinder arrangements as well as in the old VW beetles with 4 cylinders. Flat engines are also used in some Ferraris with 12 cylinders

The crankshaft is located below the cylinders on an in-line engine, at the base of the V on a V-type engine and between the cylinder banks on a flat engine. As the pistons move up and down, they turn the crankshaft just like your legs pump up and down to turn the crank that is connected to the pedals of a bicycle.

The crankshaft is located below the cylinders on an in-line engine, at the base of the V on a V-type engine and between the cylinder banks on a flat engine. As the pistons move up and down, they turn the crankshaft just like your legs pump up and down to turn the crank that is connected to the pedals of a bicycle. A cylinder head is bolted to the top of each bank of cylinders to seal the individual cylinders and contain the combustion process that takes place inside the cylinder. Most cylinder heads are made of cast aluminum or cast iron. The cylinder head contains at least one intake valve and one exhaust valve for each cylinder. This allows the air-fuel mixture to enter the cylinder and the burned exhaust gas to exit the cylinder. Engines have at least two valves per cylinder, one intake valve and one exhaust valve. Many newer engines are using multiple intake and exhaust valves per cylinder for increased engine power and efficiency. These engines are sometimes named for the number of valves that they have such as "24 Valve V6" which indicates a V-6 engine with four valves per cylinder. Modern engine designs can use anywhere from 2 to 5 valves per cylinder.

A cylinder head is bolted to the top of each bank of cylinders to seal the individual cylinders and contain the combustion process that takes place inside the cylinder. Most cylinder heads are made of cast aluminum or cast iron. The cylinder head contains at least one intake valve and one exhaust valve for each cylinder. This allows the air-fuel mixture to enter the cylinder and the burned exhaust gas to exit the cylinder. Engines have at least two valves per cylinder, one intake valve and one exhaust valve. Many newer engines are using multiple intake and exhaust valves per cylinder for increased engine power and efficiency. These engines are sometimes named for the number of valves that they have such as "24 Valve V6" which indicates a V-6 engine with four valves per cylinder. Modern engine designs can use anywhere from 2 to 5 valves per cylinder. The valves are opened and closed by means of a camshaft. A camshaft is a rotating shaft that has individual lobes for each valve. The lobe is a "bump" on one side of the shaft that pushes against a valve lifter moving it up and down. When the lobe pushes against the lifter, the lifter in turn pushes the valve open. When the lobe rotates away from the lifter, the valve is closed by a spring that is attached to the valve. A common configuration is to have one camshaft located in the engine block with the lifters connecting to the valves through a series of linkages. The camshaft must be synchronized with the crankshaft so that the camshaft makes one revolution for every two revolutions of the crankshaft. In most engines, this is done by a "Timing Chain" (similar to a bicycle chain) that connects the camshaft with the crankshaft. Newer engines have the camshaft located in the cylinder head directly over the valves. This design is more efficient but it is more costly to manufacture and requires multiple camshafts on Flat and V-type engines. It also requires much longer timing chains or timing belts which are prone to wear. Some engines have two camshafts on each head, one for the intake valves and one for the exhaust valves. These engines are called Double Overhead Camshaft (D.O.H.C.) Engines while the other type is called Single Overhead Camshaft (S.O.H.C.) Engines. Engines with the camshaft in the block are called Overhead Valve (O.H.V) Engines.

The valves are opened and closed by means of a camshaft. A camshaft is a rotating shaft that has individual lobes for each valve. The lobe is a "bump" on one side of the shaft that pushes against a valve lifter moving it up and down. When the lobe pushes against the lifter, the lifter in turn pushes the valve open. When the lobe rotates away from the lifter, the valve is closed by a spring that is attached to the valve. A common configuration is to have one camshaft located in the engine block with the lifters connecting to the valves through a series of linkages. The camshaft must be synchronized with the crankshaft so that the camshaft makes one revolution for every two revolutions of the crankshaft. In most engines, this is done by a "Timing Chain" (similar to a bicycle chain) that connects the camshaft with the crankshaft. Newer engines have the camshaft located in the cylinder head directly over the valves. This design is more efficient but it is more costly to manufacture and requires multiple camshafts on Flat and V-type engines. It also requires much longer timing chains or timing belts which are prone to wear. Some engines have two camshafts on each head, one for the intake valves and one for the exhaust valves. These engines are called Double Overhead Camshaft (D.O.H.C.) Engines while the other type is called Single Overhead Camshaft (S.O.H.C.) Engines. Engines with the camshaft in the block are called Overhead Valve (O.H.V) Engines.